Volvo Sport

Plastic fantastic

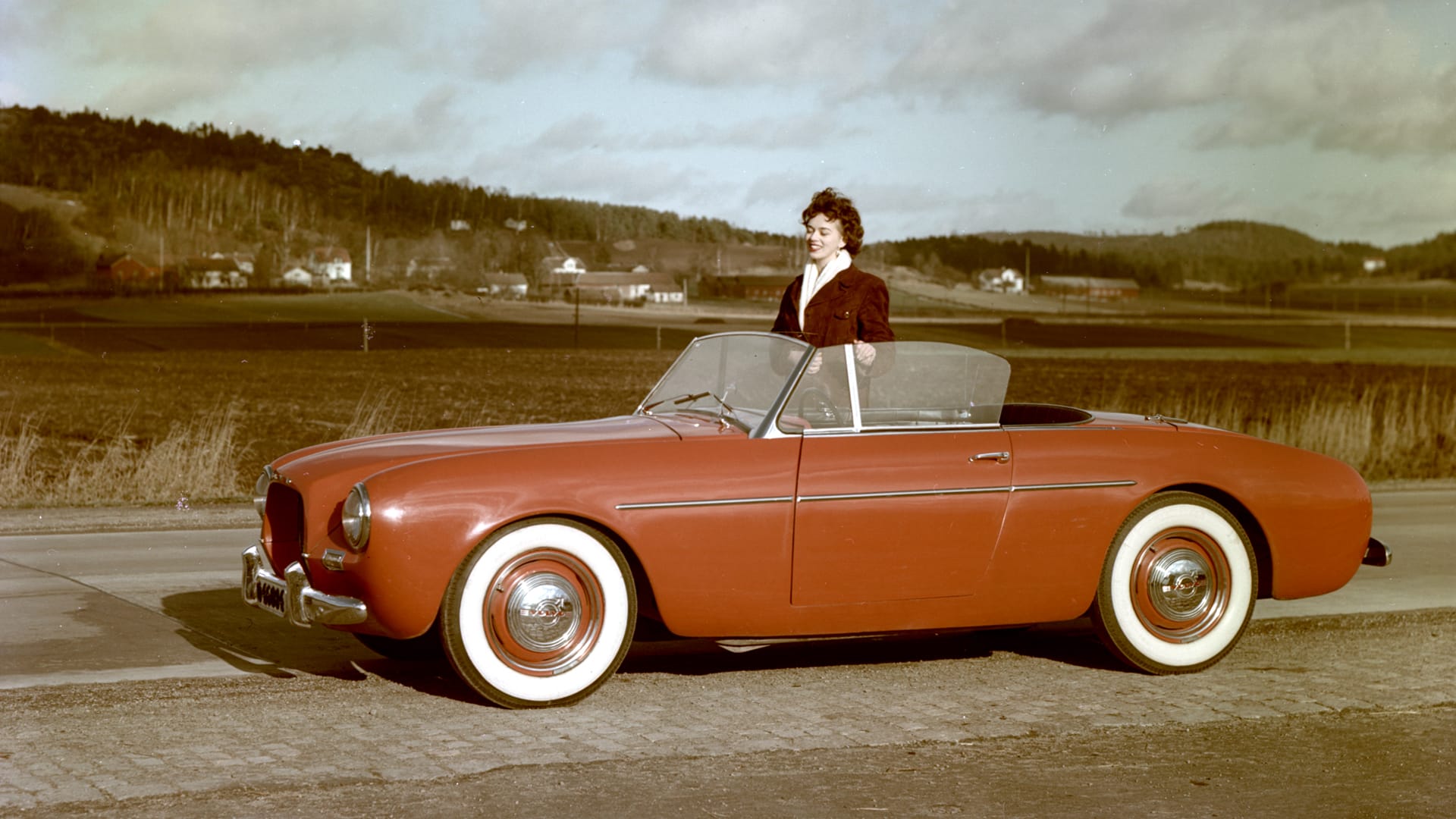

The Volvo Sport, P1900, is the predecessor of the iconic P1800 model, but it’s far less known. And it’s not hard to see why. Only 67 units were ever produced, and the model is often labeled a failure—yet it’s an interesting and beautiful failure.

Instead of traditional metal, the body is made from fiberglass-reinforced polyester. Volvo’s founder, Gustaf Larson, discovered during a 1953 trip to the USA that the then-brand-new Chevrolet Corvette was made from the same material, inspiring him to create a similar concept for Volvo. With no existing chassis to fit the plastic body onto, a new steel tube frame was developed, while the engine and gearbox were the same as in the PV444.

A sports car debut made for export

Volvo Sport – sometimes called P1900 – is part of a larger strategy: exporting cars to the United States. Volvo’s founder, Assar Gabrielsson, quickly recognises the potential of the American market. Exporting to the USA would allow Volvo to build the larger production volumes essential for the company’s survival.

For many years, Gabrielsson frequently travels to the USA to meet suppliers and business contacts, but also to keep a finger on the pulse of trends in the automotive world. Plans are already underway to ship the PV444 across the Atlantic.

During a visit in 1953, Gabrielsson notices a growing interest in sports cars, particularly European imports like MG, Jaguar, Triumph, and Porsche. A Volvo sports car, he reasons, could pave the way for the PV444. At the same time, in 1953, the Chevrolet Corvette is making waves as the hottest newcomer among sports cars. It also introduces a technical innovation: its body is made not of metal, but of fibreglass-reinforced polyester.

Plastic fantastic

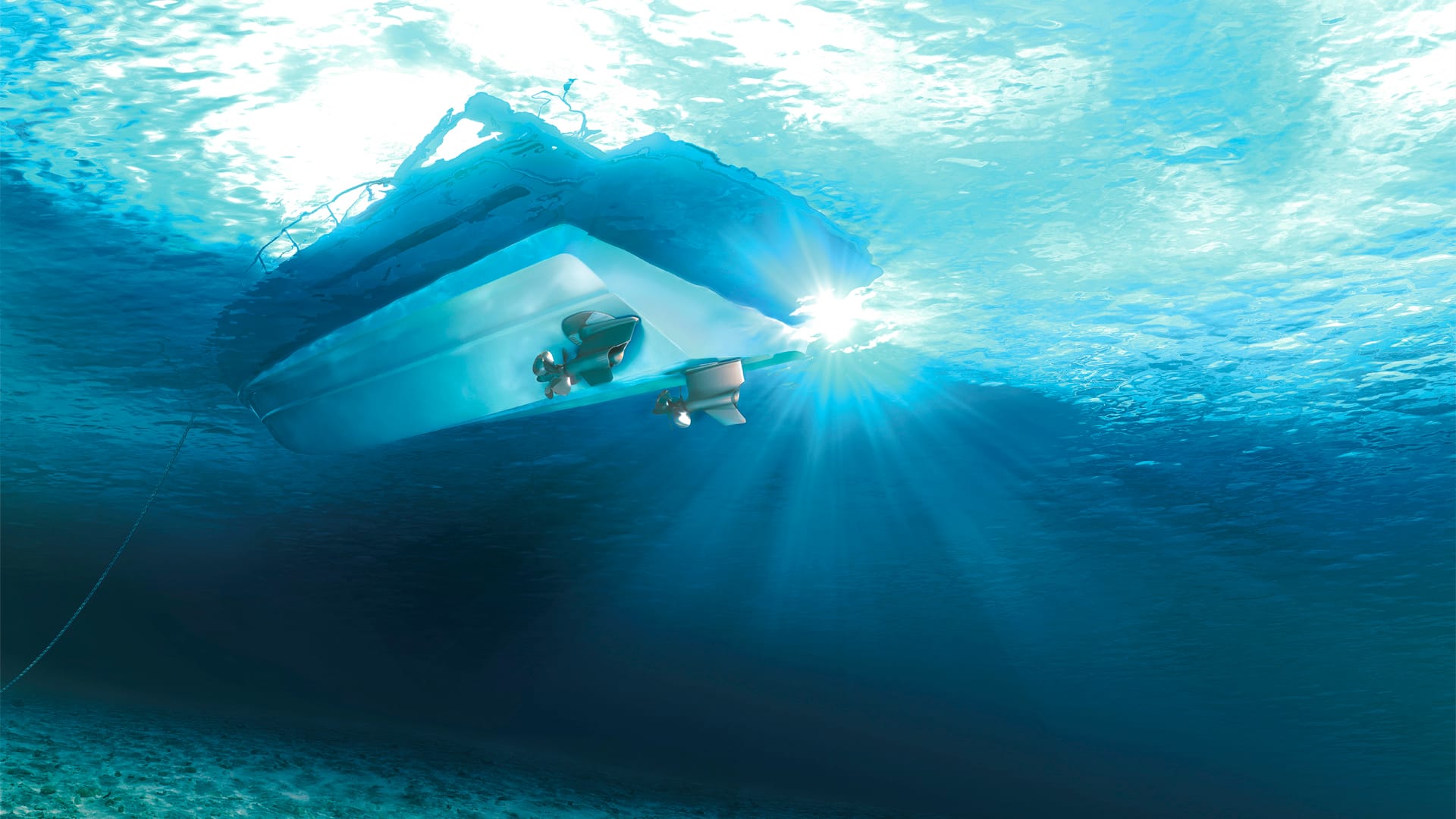

The inspiration to create a car with a plastic body comes from the California-based company Glasspar, a pioneer in fibreglass boats. In 1949, they also launch a plastic-bodied car – the Glasspar G2. During his visit to the US, Assar Gabrielsson takes the opportunity to travel to Glasspar in Costa Mesa and initiates discussions about a potential collaboration. On the spot, they agree that Glasspar will supply fibreglass bodies for Volvo.

Plastic bodies offer several advantages. They are lighter than metal, a clear benefit for a sports car, and the investment required for pressing tools is minimal, making the approach economically attractive for Volvo.

From blueprint to reality – Gabrielsson’s plastic vision on fast-forward

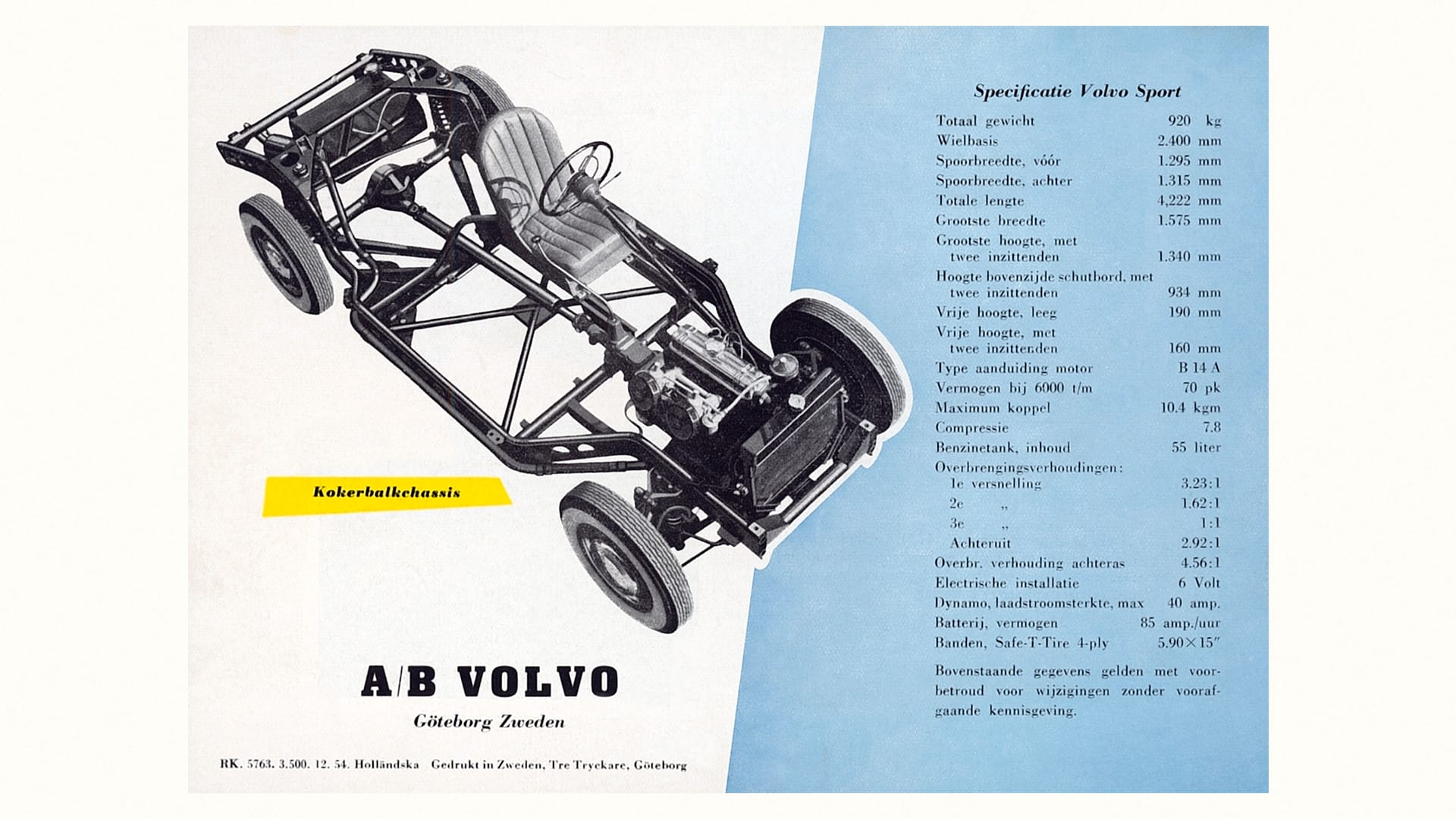

The Volvo Sport project moves at lightning speed. Designs for the car are sent from the USA to Gothenburg with Gabrielsson’s order to find a suitable chassis for the newly ordered fibreglass bodies. Easier said than done – since the new PV444 lacks a frame, an entirely new chassis has to be developed. Made from steel tubing, it includes sturdy crossbeams, side rails, and additional reinforcement with a cross brace.

To keep costs down, parts are sourced from competitor cars: tail lights from Chevrolet, interior door handles from Humber, and exterior handles from Morris Oxford. Most components, however, are pulled from the PV444, including the gearbox, rear axle, front suspension, and brakes. The wheelbase is shortened by 200 mm to provide sportier handling.

Three gears, 70 hp, and 920 kilos

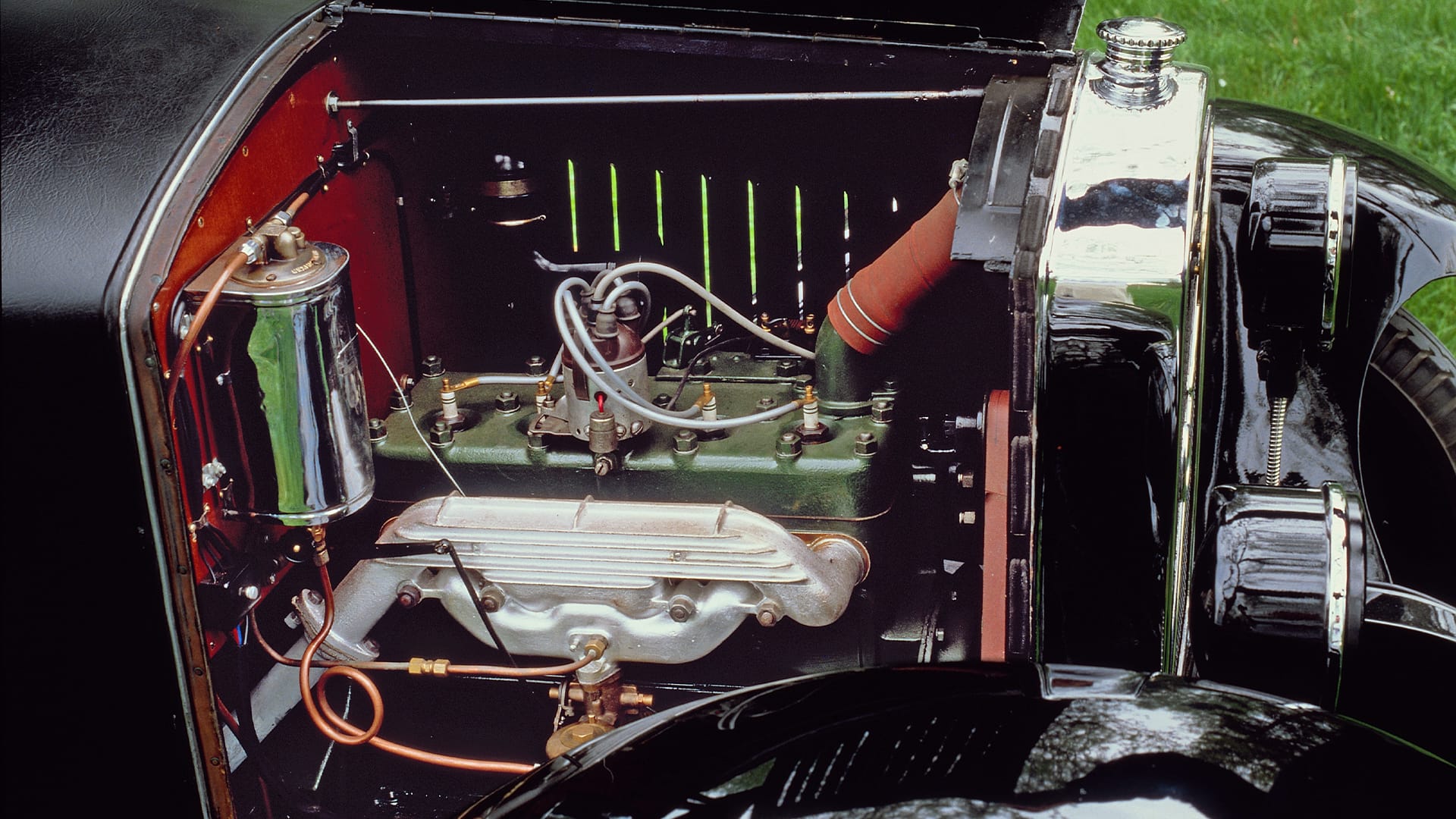

On paper, the drivetrain isn’t exactly cutting-edge. The three-speed gearbox and 1.4-litre B4B engine come from the PV444, though the engine is upgraded with dual SU carburettors, a different camshaft, new valves, and a reworked cylinder head for higher compression. Renamed the B14A, it now produces 70 hp, compared to the standard 51 hp, and gets a red engine block instead of the usual green. While 70 hp isn’t much, it’s less of a problem given the Volvo Sport’s low weight of just 920 kg (with a service weight of 1,040 kg). Its top speed is listed as 155 km/h.

Made in Sweden, but not for Swedish roads

Development moves quickly, and by 2 June 1954, the Volvo Sport makes its grand debut at Torslanda Airport in Gothenburg. Three hastily assembled cars are presented, all hardtops without convertible roofs. The side windows can’t be lowered into the doors, and both the bonnet and boot sit on top of the body, drawing criticism. Volvo’s management makes it clear that this isn’t a car for Sweden but is solely intended for export, primarily to the USA. At the launch, they announce: “Since an open car is unsuitable for Nordic climates, the Volvo Sport will be sold exclusively in our southern export markets.”

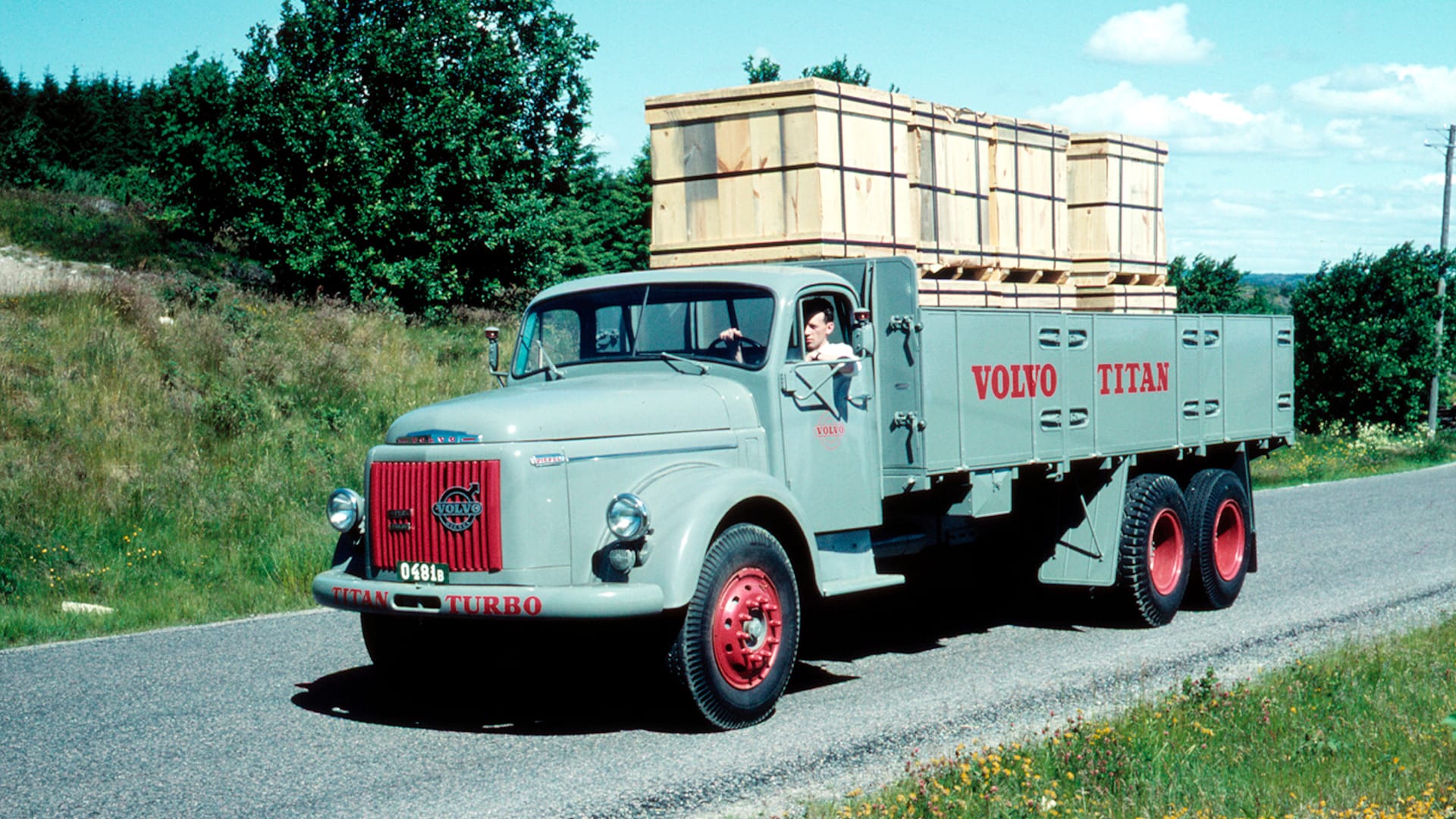

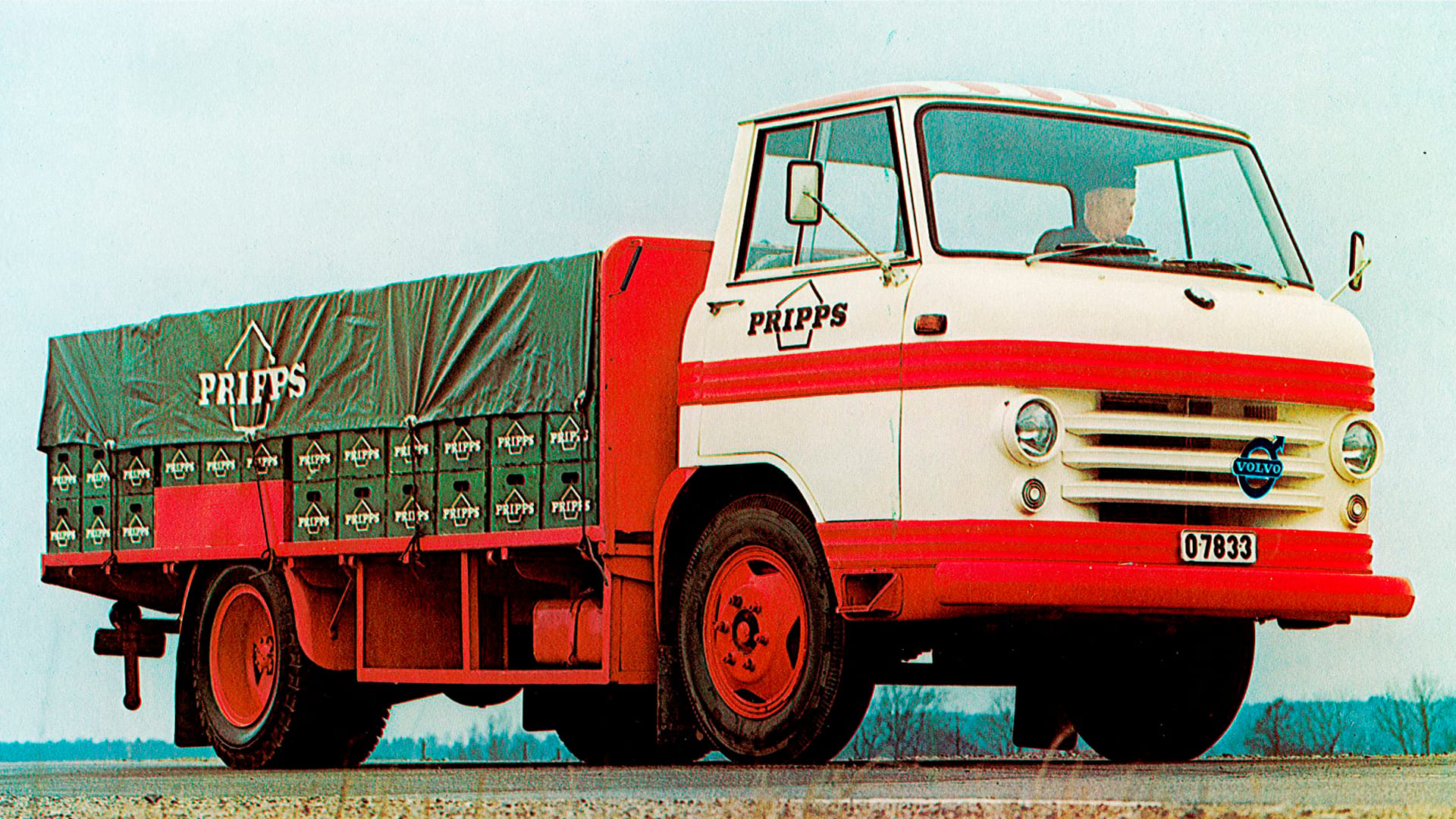

Newspapers further emphasise this point, stating: “The test cars that will appear on Swedish roads will only be in the hands of Volvo and its dealers. Enthusiasts are asked not to overwhelm the phones trying to get one.” Despite this, a showcase tour is arranged across Sweden, where the P1900 – as it’s now often called – shares the spotlight with the Titan Turbo, the world’s first mass-produced turbocharged truck.

Gabrielsson’s farewell: a short-lived sports car

It takes two years for Volvo Sport production to begin. Volvo engineers Helmer Petterson – whose son Pelle would later design the P1800 – and Pelle Nyström take one of the cars on a 1,600 km test drive through southern Europe, with a detour into North Africa. Official reports are positive, but internally, Helmer Petterson reports significant issues. The frame is too weak, the body mounts wear out, and the door hinges are substandard. In short, it’s not the quality Volvo is known for.

Customers are equally sceptical, both about the technology and the relatively high price of SEK 19,700. For comparison, in autumn 2024, a Volvo Sport sells for SEK 1,450,000 despite being damaged and lacking full originality. In 1956, only 44 cars are produced, with the first deliveries going to customers in South Africa, Brazil, Morocco, and the USA – though most surprisingly end up in Sweden, despite earlier statements.

The weak sales are a disappointment for Assar Gabrielsson, who in 1956 is preparing to retire from Volvo. The Volvo Sport was meant to be his parting gift to the company. His successor, Gunnar Engellau, is far less forgiving. After driving the P1900 for a weekend, he reportedly says, “I thought it would fall apart!” This marks the end of the line for the model.

From plastic failure to steel success – the road to P1800

In 1957, just 23 more cars are built, the last on 21 May 1957. With only 67 units produced, Volvo’s venture into fibreglass sports cars comes to an end. Of these, 38 remain in Sweden. While Engellau dismisses the car itself, he understands the reasoning behind it and immediately begins a new sports car project. Four years later, the P1800 is unveiled – this time with a steel body.