Volvo Penta IPS Drive

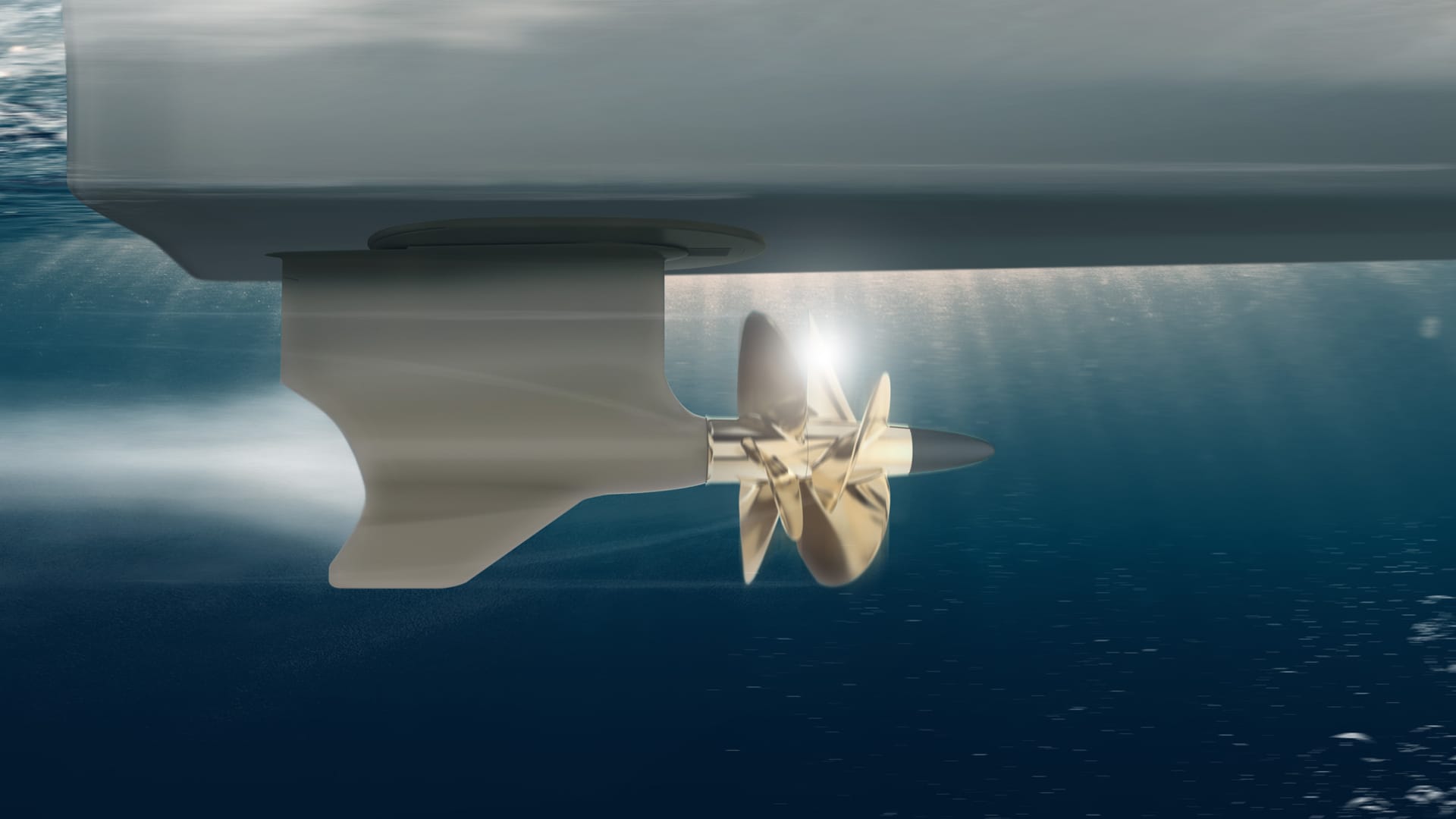

Pulled, not pushed

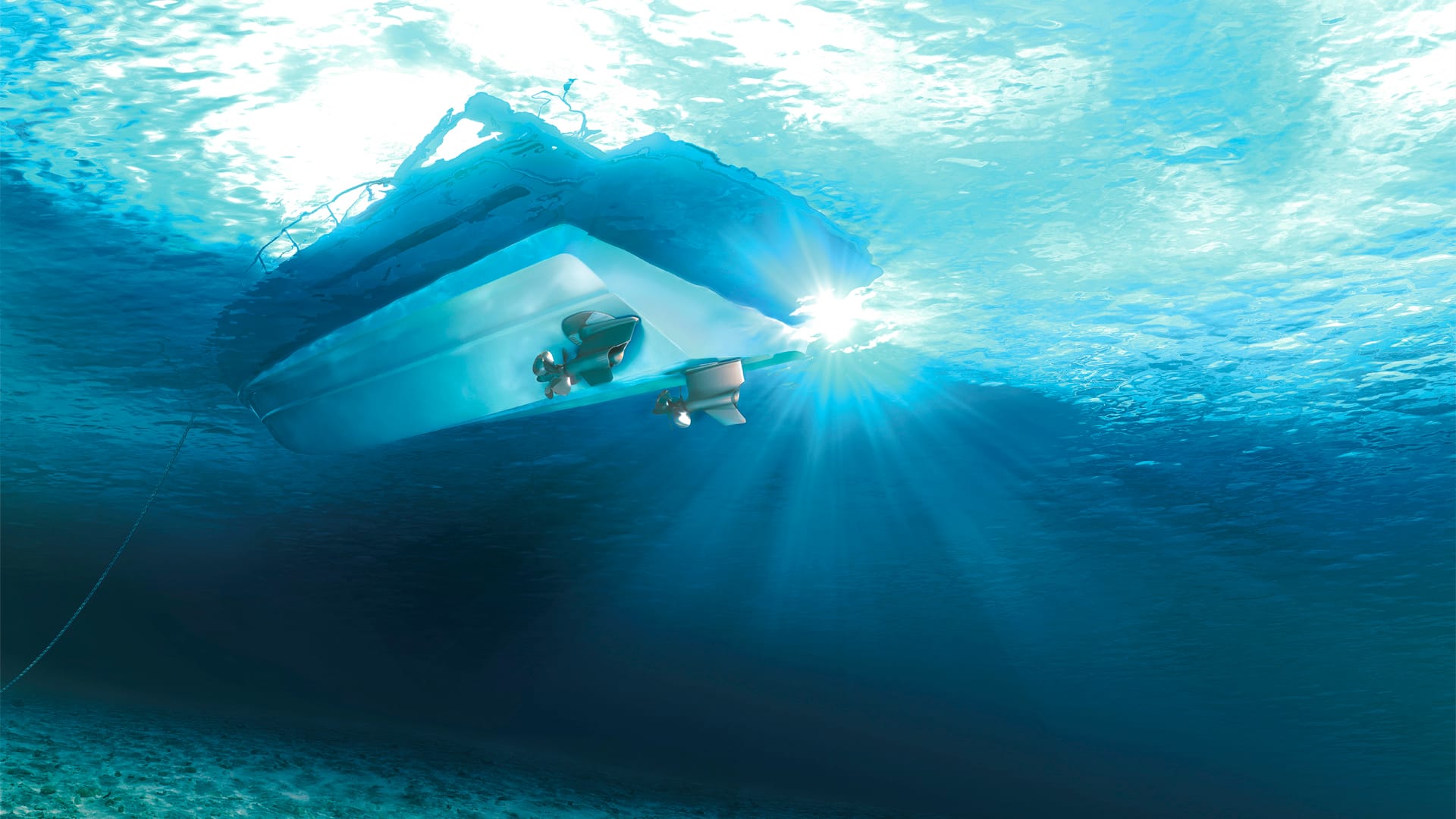

Traditionally, a boat is pushed forward by the propeller. Launched in 2005, the Volvo Penta IPS Drive (Inboard Performance System) actually works the opposite way.

With two forward-facing, counter-rotating propellers, the boat is instead pulled through the water.

This system offers several advantages over a straight shaft installation: range increases by up to 40 percent, top speed by up to 20 percent, while fuel consumption—and thus CO₂ emissions—decreases by up to 30 per cent. In addition to this, noise levels are cut in half. Another major advantage is the boat's exceptional maneuverability. Instead of managing multiple controls at once, the boat can be easily steered with a joystick.

Redefining marine propulsion

Volvo Penta repeatedly rewrites the rules for powering boats. It begins with the Aquamatic, unveiled at the New York Motor Boat Show in January 1959. This innovation combines the best of two worlds: the engine remains inboard, while the propeller is placed outboard. In 1982, the Duoprop drive introduces the next breakthrough with two counter-rotating propellers on the same shaft. However, many believe that the IPS (Inboard Performance System) is the most significant revolution, redefining the concept of "Easy Boating."

The inboard killer that made waves

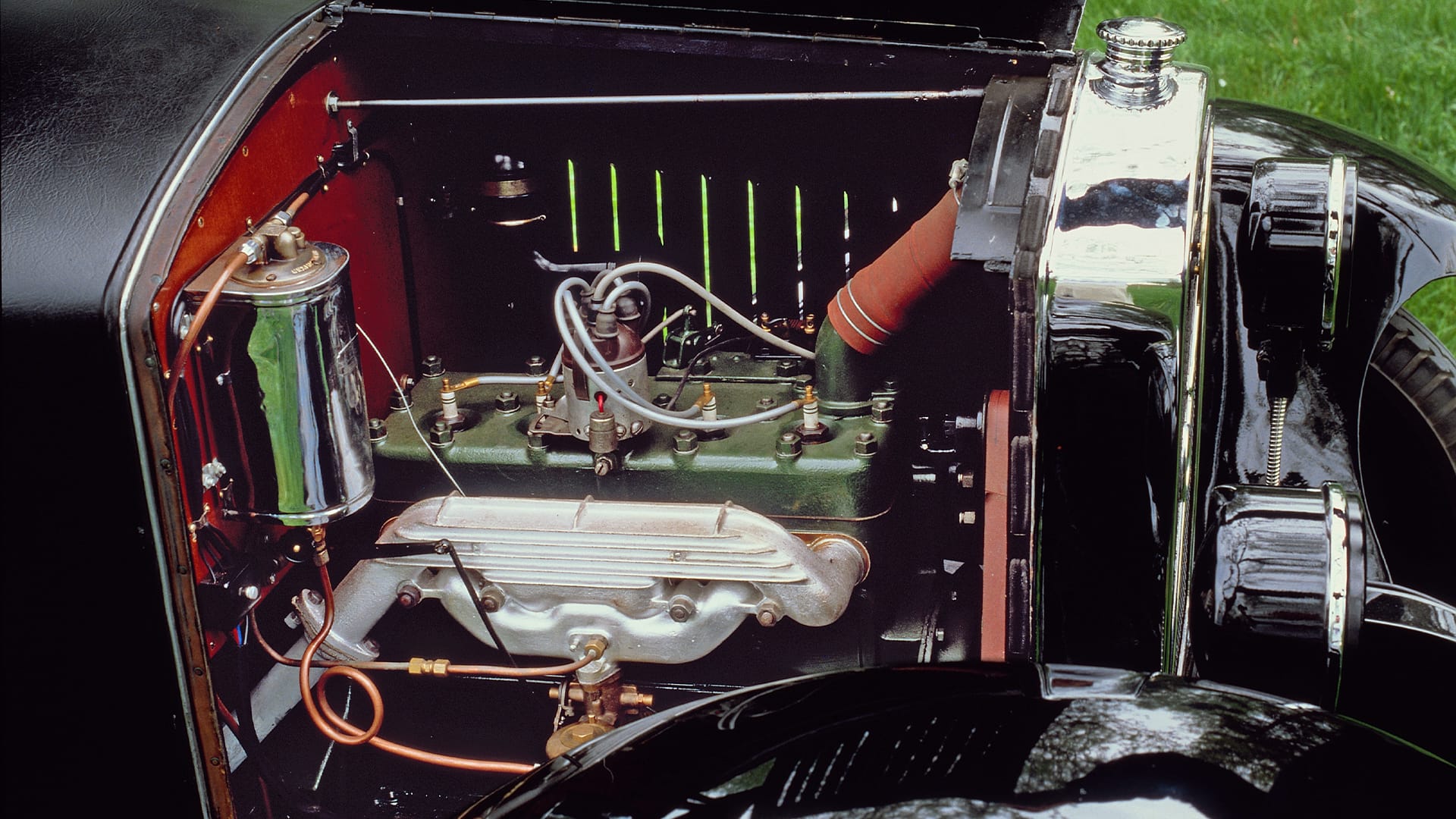

IPS debuts at the London Boat Show in 2005, where many of the 150,000 visitors marvel at how Volvo Penta seems to make the impossible possible. The idea for IPS originates in the late 1990s as a directive from Göran Gummesson, who has held various roles at Volvo Penta since 1991 and becomes its CEO in 2004. Gummesson seeks an entirely new propulsion system – a so-called "inboard killer" – to offer customers. At the time, large yachts in the 45–55-foot range are dominated by inboard systems, consisting of an engine connected to a shaft running diagonally through the hull to a propeller and rudder.

These systems take up significant space – nearly half the boat's volume – while customers demand more onboard living space and better performance. Increasing speed with an inboard system requires a larger, heavier engine, which ironically reduces performance, creating a classic Catch-22.

From push to pull

These systems take up significant space – nearly half the boat's volume – while customers demand more onboard living space and better performance. Increasing speed with an inboard system requires a larger, heavier engine, which ironically reduces performance, creating a classic Catch-22.

The innovative Aquamatic, though groundbreaking, is unsuitable for the powerful engines needed for larger boats. In spring 1999, a team of engineers begins experimenting with ideas for an "inboard killer". Much of the work is carried out in the US, where Volvo Penta also operates. Early on, the concept of forward-facing, counter-rotating propellers emerges – an idea that, while not entirely new, is highly effective. This system pulls the boat through the water rather than pushing it, with all propulsion forces acting parallel to the hull’s bottom, ensuring maximum efficiency.

More speed, less noise – and room for an extra cabin

With IPS, traditional components like axles, struts, and separate rudders become unnecessary. The forward-facing propellers always encounter clean water, and exhaust gases are directed aft, reducing noise. IPS requires smaller engines to achieve the same performance as traditional systems and occupies only a third of the space compared to inboard setups. This frees up significant room for additional cabins or other features.

Tests show that IPS delivers up to 20% higher top speed, up to 15% better acceleration, and up to 30% lower fuel consumption. It also reduces noise and vibration by up to 50%.

Saffron beginnings: IPS sets sail for the future

When the development work begins, a Carver Trojan 400 boat is borrowed to serve as a testbed. It is completely stripped down, essentially just a shell. The team finds a diesel engine, adds a compressor, and manages to achieve 300 horsepower. To give the setup a bit of flair, they acquire paint from the Volvo Cars factory in Uddevalla, which at the time manufactures the C70. The factory has overstocked on paint in the colour "Saffron Pearl," and the Volvo Penta team gets hold of some of this surplus to paint the engine and drive unit.

The first test runs of what will become the IPS system take place off the coast of Norfolk, Virginia, in the USA, not far from the world’s largest naval base operated by the US Navy. The system surprises everyone: its efficiency is remarkable, and its performance is so impressive that someone initially believes there is a mistake in the speed readings – thinking the measurements are in miles per hour instead of knots. However, a serious problem is soon discovered: the boat is nearly impossible to steer. While it handles straight-line, high-speed cruising well, manoeuvring in a harbour is hopeless.

The system surprises everyone: its efficiency is remarkable, and its performance is so impressive that someone initially believes there is a mistake in the speed readings – thinking the measurements are in miles per hour instead of knots.

The limits of hydraulic and the first crisis

The solution comes with the idea of making the pods steerable. Hydraulics provide an answer, and the first successful trial is celebrated with champagne. Yet the celebration is short-lived; the components fail under pressure. Water forces twist the pods, causing oil leaks and water ingress. At one point, the boat spins in a full circle due to the damaged hydraulics. This critical moment raises the question: is it time to give up, to simply surrender?

Electronics take over – a new era of steering

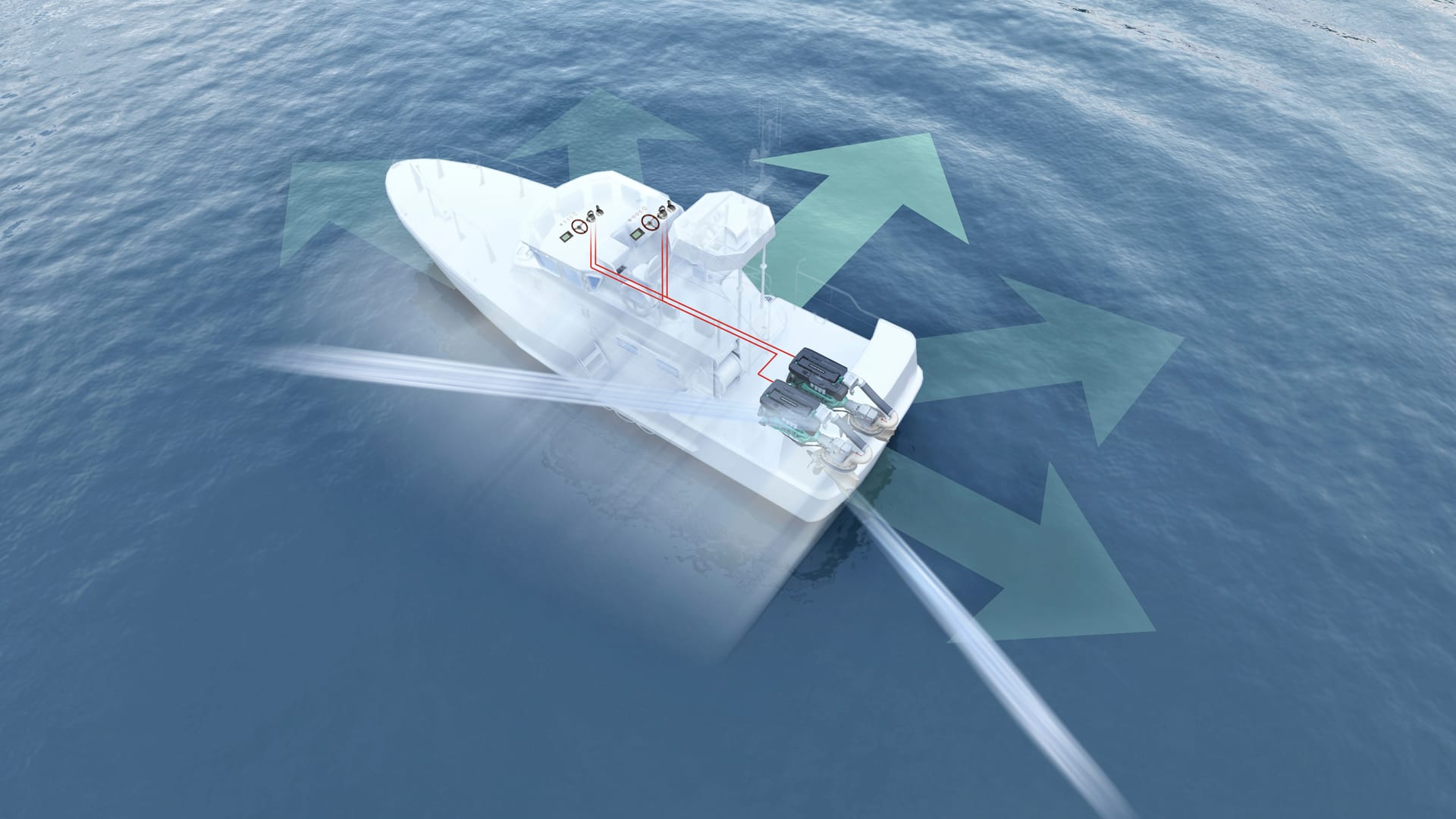

The breakthrough arrives when someone suggests independently steerable pods. This requires electronic controls rather than hydraulics, leading to the creation of the world’s first propulsion system without a mechanical or hydraulic connection between the steering wheel and the drive units.

By angling the pods slightly to form a "V," water forces are minimised, allowing precise steering. With a maximum tilt of just 30 degrees per pod, the system enables full control, even sideways docking in tight spaces.

No holes in the hull

There are still plenty of question marks surrounding the project, which challenges much of the conventional thinking. For instance, what happens if the boat runs aground? The two pods are mounted in sizeable holes in the hull, and the potential consequences could be catastrophic.

The team decides that under no circumstances should a collision create a hole that allows water to flood in. The solution? The pods are designed to simply snap off on impact – much like breaking off an icicle – leaving the hull intact.

The IPS-package: easier for boat builders and customers

Beyond its efficiency and ease of manoeuvring, IPS offers a host of other benefits for both customers and Volvo Penta. With traditional shaft installations, boatbuilders typically source various components from different suppliers. IPS, however, comes as a complete package: engine, drive, gearbox, propeller, steering system, muffler, cooling system, and electronics. All the boatbuilder needs to do is make one call, provide the boat's weight, and Volvo Penta delivers two boxes with everything included.

On top of that, IPS is incredibly quick to install. Building a boat with an inboard setup takes 25 weeks, with the engine and shaft arriving halfway through. IPS can be installed just 2–3 weeks before delivery. Since its debut in London in 2005, IPS has been continuously refined. By the following year, a clever addition arrives: joystick steering for easier docking. The system later evolves into the Electronic Vessel Control (EVC) options, integrating docking and navigation with autopilot and GPS.

Making the difficult easy

At the 2021 Consumer Electronics Show (CES) in Las Vegas, Volvo Penta participates for the first time and launches its Assisted Docking system. The system is named a finalist by Engadget for "Best of CES" in the Transportation Technology category. The reasoning? “The Volvo Penta Assisted Docking system is essentially the same as the assisted parking feature in many luxury cars – but for boats. Using GPS and onboard sensors, it can make on-the-fly adjustments to dock your yacht, even in the tightest spaces.”

20 years of Volvo Penta IPS Drive

Over the years, various engine options have been added, and the system has continued to evolve. In 2025, marking the 20th anniversary of its London debut, Volvo Penta launches a new platform for professional boats and superyachts. This becomes the fifth and most powerful platform in the lineup. Among its features is the Volvo Penta IPS 40 drive – a new concept with dual power input. It is also designed to work with multiple energy sources, including combustion engines running on renewable fuels, hybrid solutions, and fully electric propulsion.

Five years after its launch, 10,000 IPS units are sold. By the 10th anniversary, that number grows to 16,000, and by the time of the 20th anniversary, over 43,000 IPS units have been delivered."