Volvo ECC

A trailblazer

The Volvo Environmental Concept Car (ECC) marks a revolution, both externally and internally. The design provides a clear glimpse of the S80, which is launched six years later. The newly hired design chief, Peter Horbury, believes that the ECC allows him to forever change the appearance of Volvo cars.

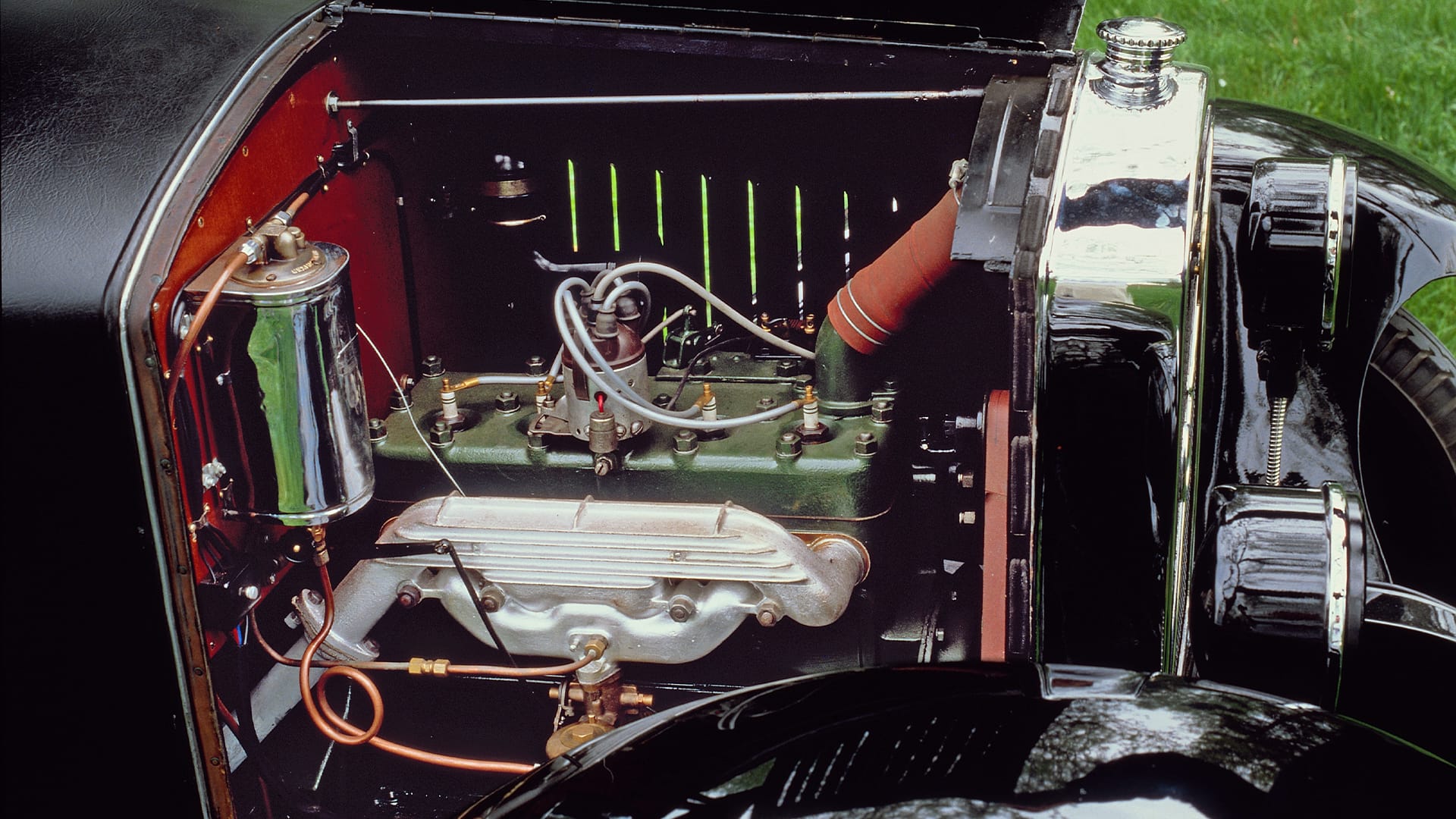

The technology is equally exciting: the car is built with recyclable materials, such as an aluminium chassis and a cork interior, and is powered by an electric motor. The batteries can be charged either from a standard wall socket or from a gas turbine via a high-speed generator.

In the ECC - which is drivable - the gas turbine is powered by diesel, but all liquid fuels can be used. The range on battery power is 85 km, but it extends to a full 670 kms if the gas turbine is also engaged.

The ECC is presented in 1992 as a study on how a safe, environmentally friendly, and comfortable family car could look like in the year 2000. Behind the development of the ECC is the Volvo Monitoring and Concept Center (VMCC) in California.

Plug-in hybrids

The basic principle of the car – a plug-in hybrid – becomes popular 20 years later, also at Volvo. Plug-in hybrids combine an internal combustion engine with an electric motor and batteries that are charged via cable, considered for a time to be the best of both worlds. The car can be driven emission-free in city traffic while it has sufficient range for longer trips. Volvo's first plug-in hybrid, V60 D6, goes into production in 2012, combining an electric motor with a diesel engine.

Turbine drive

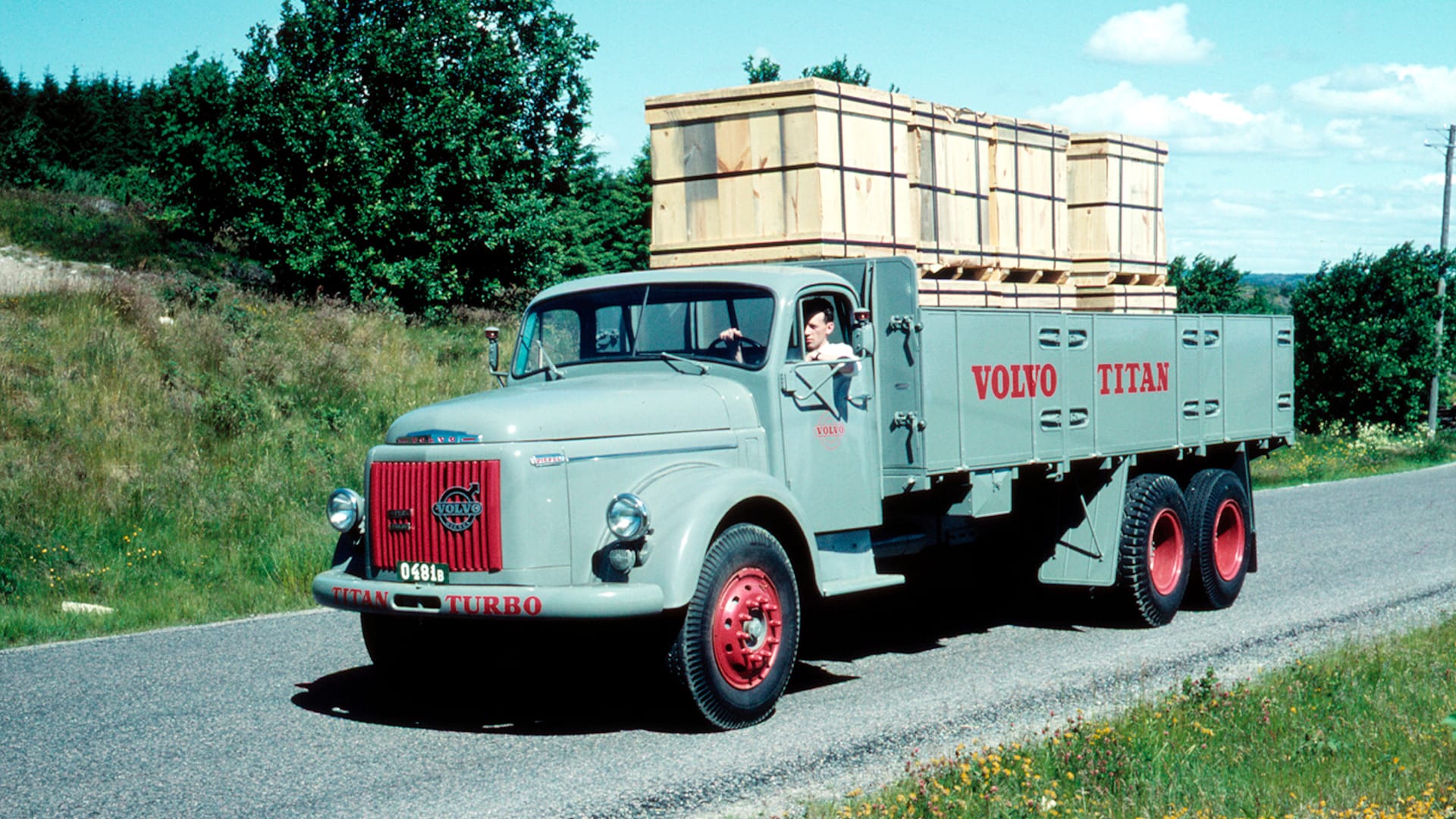

With the ECC, a different, more spectacular strategy is chosen. The driving wheels always get power from an electric motor, never from an internal combustion engine as most later plug-in hybrids models will do. In fact, there is no traditional internal combustion engine at all in the ECC; instead, there's a diesel-powered gas turbine combined with a high-speed generator, both working at the same, very high speed. The turbine is developed by United Turbine in Malmö, a subsidiary of Volvo Aero (later GKN Aerospace), which has high expertise in the field.

Charging with a cable

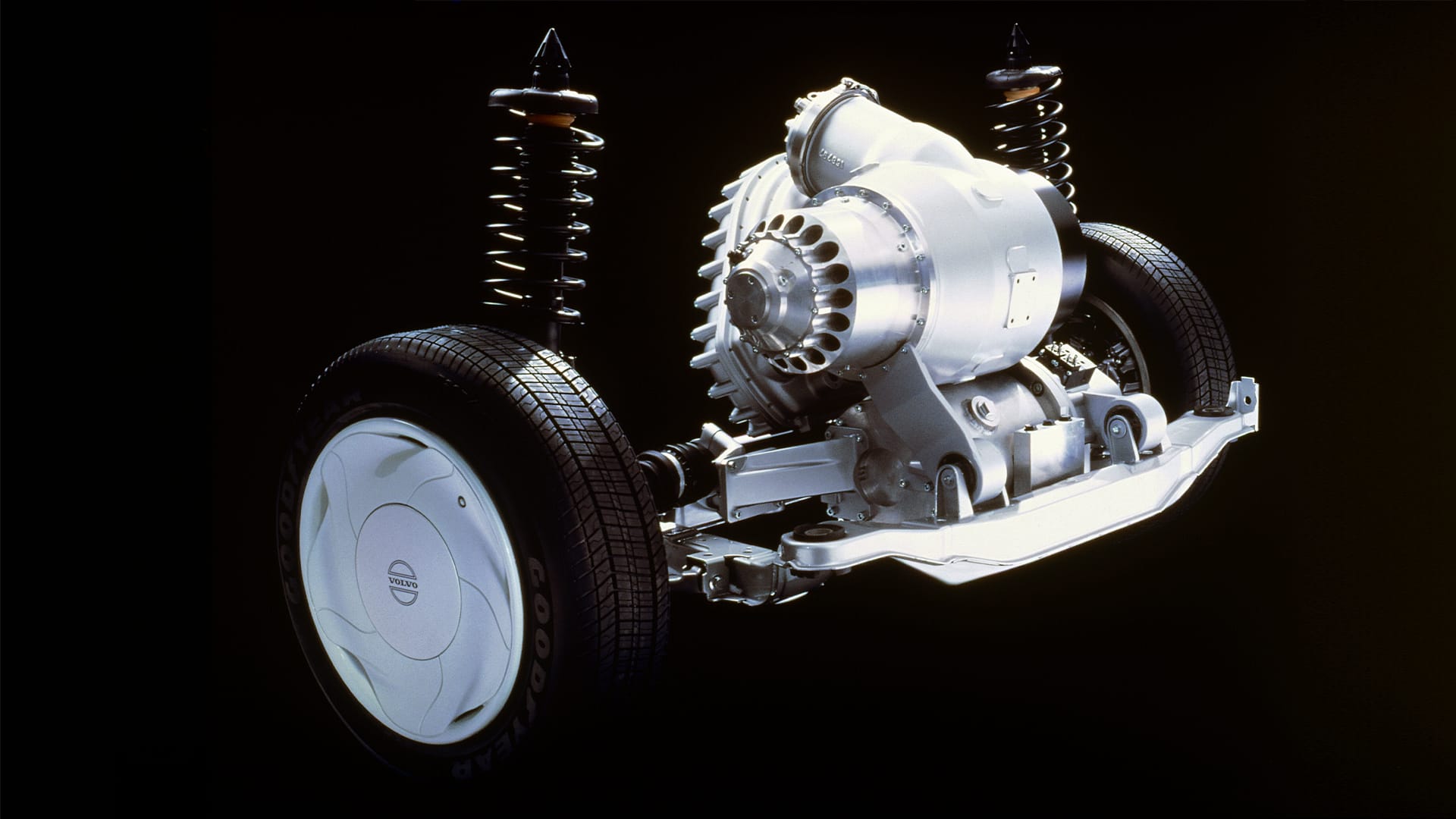

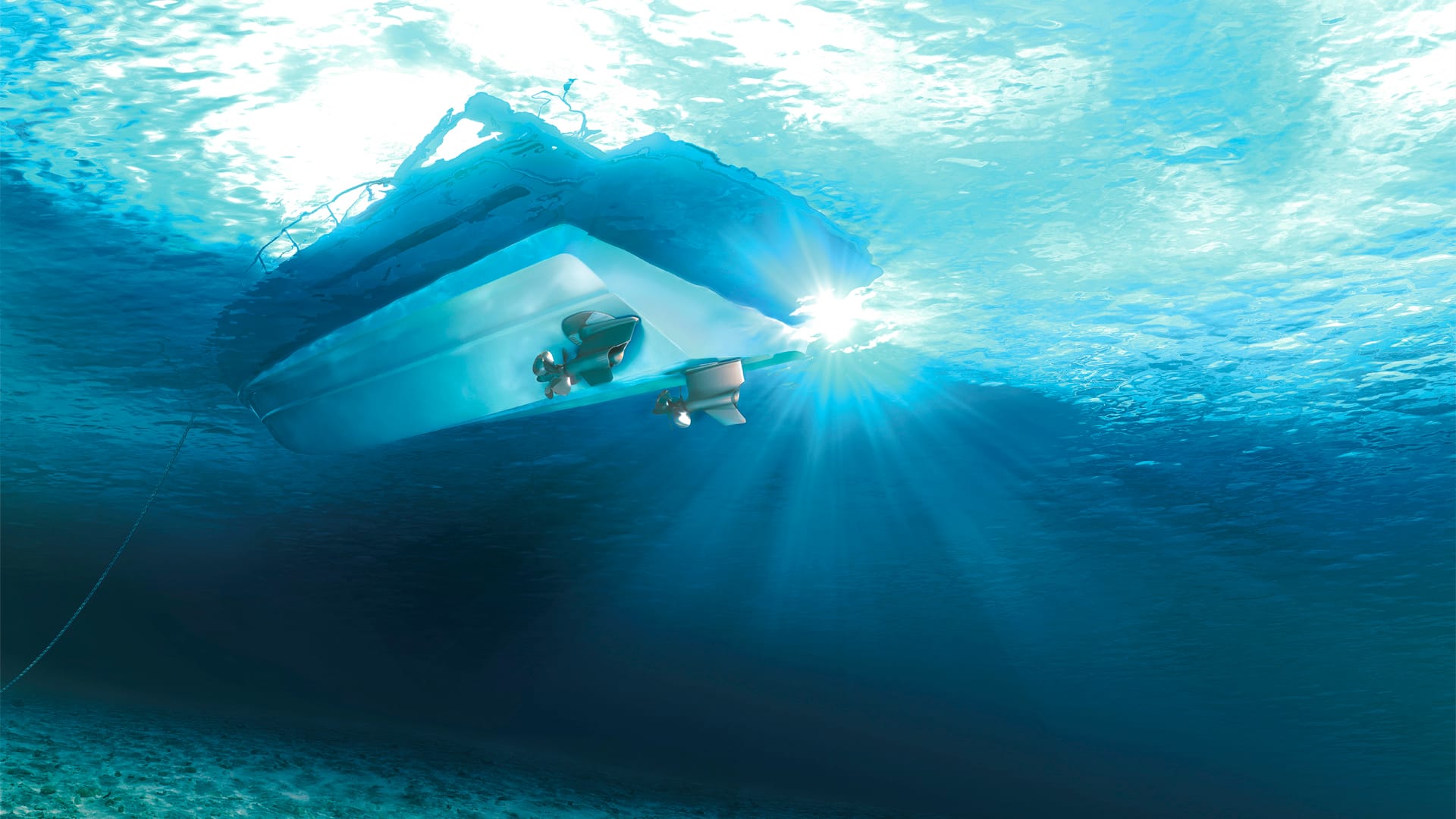

The batteries in almost all plug-in hybrids are charged with a cable, either at home via a charging box or at a charging station. The batteries in ECC are also charged this way, but when they are depleted, the electric motor gets power from the gas turbine via the high-speed generator. Power is transmitted through a two-speed automatic transmission. The driveline comes from Volvo's gearbox factory in Köping (later GKN Driveline), while ABB is responsible for the electronics: electric motor, generator, control system, power electronics, and DC converter.

Good performance

The electric range is initially stated at 85-90 km, but later, the figure of 130 km is also been mentioned. With the gas turbine engaged, the range increases to 670 km. In ECC, it is powered by diesel, but virtually any liquid fuel can be used, such as biofuels. The electric motor has a modest output of 96 hp, and with the help of the gas turbine, the top speed reaches around 150 km/h, while 0-100 km/h takes 13 seconds. "This is very good for an electric car," says automotive journalist Christer Glenning on SVT's "Traffic Magazine." He also describes the ride in ECC as "almost silent, with just a whisper from the electric motor."

Lightweight

There is another point to the technical solution in the ECC. Both the electric motor and the gas turbine are very light. Additionally, since the body is made of aluminium – which reduces weight by 215 kilograms compared to a steel body – the ECC weighs only 1,580 kilograms. Of that, the batteries alone account for 315 kilograms. They are of the nickel-cadmium type, a technology that has many good properties: high power density, long lifespan, and good performance at low temperatures. However, the toxic and environmentally hazardous heavy metal cadmium leads to the prohibition of this battery type later on.

Six years prior

The ECC is made from materials with low environmental impact and is prepared to be 100% recyclable. The year before ECC is presented, Volvo has premiered the 850 model, which takes very small steps design-wise. But when Peter Horbury starts as design chief at Volvo the same year, he realizes that it is time for a substantial renewal. American designerDoug Frasher is involved in the work on the ECC, and later designs the S80,launched six years later closely resembling ECC in many aspects. When ECC premieres at the Paris Motor Show in 1992, visitors get more than a sneak peek at what Volvo's next big model will look like.

Low drag coefficient

The ECC has a good aerodynamic shape, and the coefficient of drag (CD) is as low as 0.23. ECC is supposed to be credible as a family car and has the safety features found in the 850, including the Side Impact Protection System (SIPS). An integrated child seat is available in the middle rear seat.