VESC

Towards safer standards

Ralph Nader's book "Unsafe at Any Speed", published in 1965, ignites a heated debate on traffic safety. The issue becomes political, leading to the establishment of authorities and compels the automotive industry to prioritize safety.

In the USA, car manufacturers receive government support to develop concept cars. However, Volvo takes matters into their own hands and creates the Volvo Experimental Safety Car (VESC), showcasing it at the Geneva Motor Show in 1972. This marks a milestone, positioning Volvo at the forefront of automotive safety.

The VESC incorporates technologies that won’t appear in cars for decades: airbags, a rearview camera, anti-lock brakes, and bumpers designed to withstand frontal crashes at 80 km/h.

In 1970, the US Department of Transportation (DOT) launches a program to improve car crash safety. Initiated by NATO, which was then broadening its focus to include social and civilian matters, the program aims to develop cars with significantly higher safety standards than those available on the market. To this end, DOT formulates an 82-point checklist for the Experimental Safety Vehicles (ESV) conference, which still convenes annually. While the initial manufacturers tasked with creating safety cars are all American - including General Motors, aerospace manufacturer Fairchild Hiller, and American Machine & Foundry (AMF) - foreign manufacturers like Fiat and Mercedes are also invited to participate.

Ahead of the curve

When the program commences, Volvo is already working on the VESC, serving as a response to initiatives in the USA. Debuting at the 1972 Geneva Motor Show, alongside cars like the Ford Granada and Ferrari Dino 246 GTS, the VESC positiones Volvo as a leader in safety car development. Meeting 70 of the 82 points on the DOT checklist, it exceeds internal Volvo standards, which were four times higher than ESV requirements in some aspects.

Ten examples

The VESC isn’t just a single car, but is rather produced in ten different variations, each with unique features and safety solutions. Serving both as an internal tool to gather ideas and as a showcase the public, three cars are fully assembled, while the remaining bodies (derived from the discontinued 1560 new car project) are used for various tests at Volvo's Safety Centre, established in 1972.

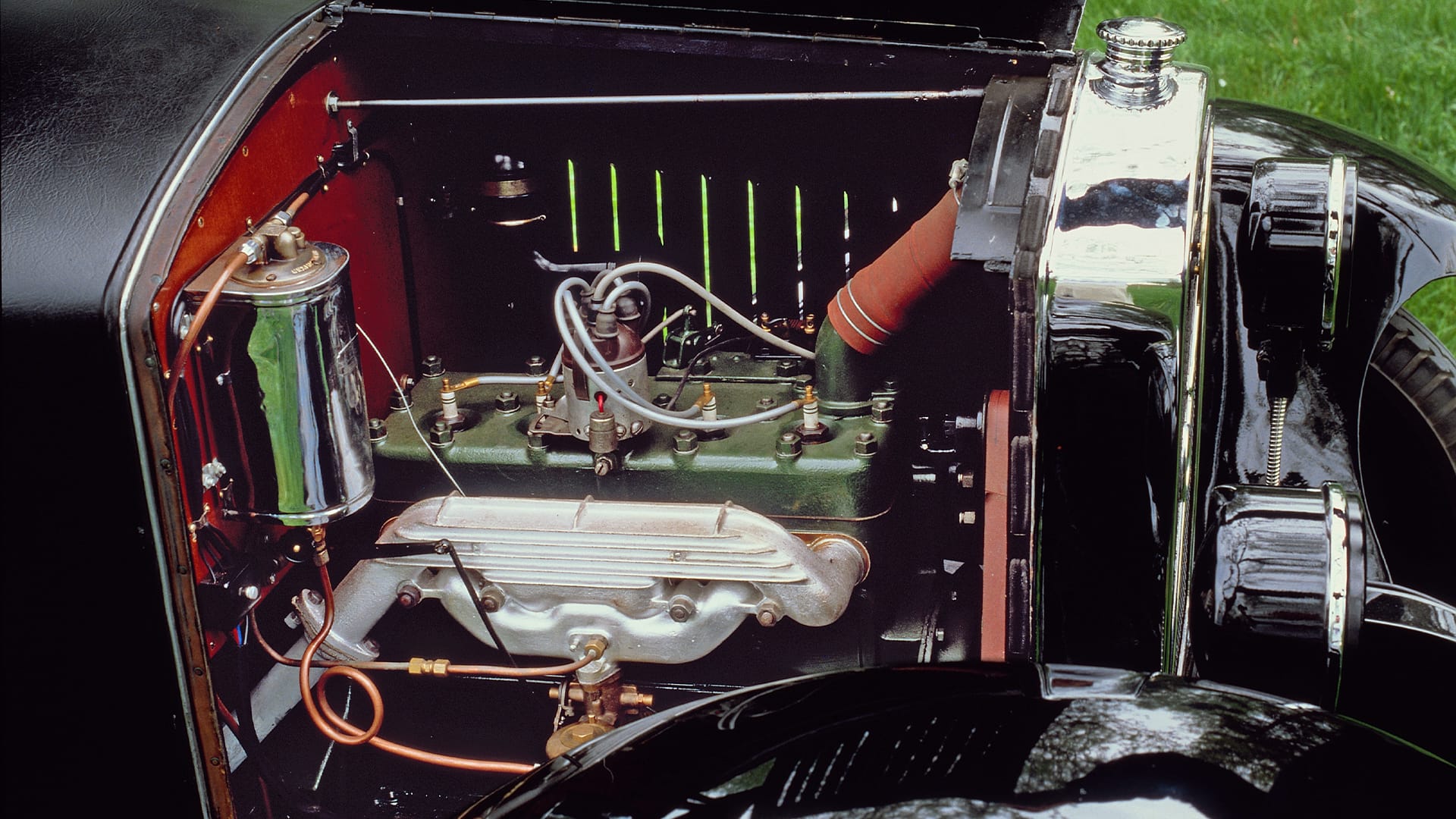

Absorbing impact

The appearance of the VESC itself hints at its safety features. Designed to protect occupants in an 80 km/h frontal collision, both the front and rear ends are constructed to absorb maximum crash energy. Consequently, the VESC is lengthy, measuring 552 cm. The front bumper can be pushed back 18 cm before the body absorbs the impact, and the car can withstand collisions at 16 km/h (10 mph) without sustaining damage, meeting American safety standards.

Roof integrity

The doors contain protective beams, and the roof is designed like a cage. The requirement is for the car to withstand a roof landing from a height of 2.4 meters without the roof depressing more than 75 mm. In the event of a crash, the engine and gearbox are forced below the floor, partly through a metal plate and partly through the construction of the rear engine mount. The steering column feature a spring mechanism that rapidly retracts the steering wheel 15 cm from the driver in a frontal collision. Hidden neck supports are located in the front seat’s back and deploy in a crash.

Back-up camera 50 years ahead

The various cars also feature a multitude of unique solutions. One has passive safety belts that automatically tighten when the driver releases the handbrake; another has airbags in both the steering wheel and glove compartment; some has anti-lock brakes, while others have reverse warning systems. One car even includes a back-up camera, a feature only mandated by law in the USA in 2018 and the EU in 2021.

Moose test

Unlike many other manufacturers that focuse solely on passive safety technology in their safety cars, Volvo ensures that their vehicles also boast effective brakes, a stable and predictable chassis, and responsive steering for handling rapid maneuvers, a requirement later known as the "moose test."

Adopted by the 200 Series

The VESC also features headlight washers, a feature that would later disappear from many cars. Much of what is showcased in the VESC makes its way into Volvo's production cars, starting with the 200 Series launched two years later in 1974. While the extreme front end of the VESC is toned down, its distinctive features remain, making the 200 Series one of the safest cars on the market at the time.