BM-Volvo DR860

Rocking towards success

Perhaps it looks like a duck rocking through the terrain, the BM-Volvo DR860. To navigate through difficult conditions, the dumper can swing right and left, a technique known as duck-walking.

The model is the world's first mass-produced, four-wheel-drive, frame-steered dumper with a bogie system, where conventional steering is replaced by a joint between the wagon and the tractor. Behind the construction stands Carl Lihnell from Braås in Småland, where the dumper is also manufactured. The vehicle at the World of Volvo is from 1969.

The mobility creates entirely new possibilities in road projects, where previously, temporary access roads had to be built. Instead, the dumper can be driven straight through the terrain, saving both time and money - and making Volvo a world leader in dumpers.

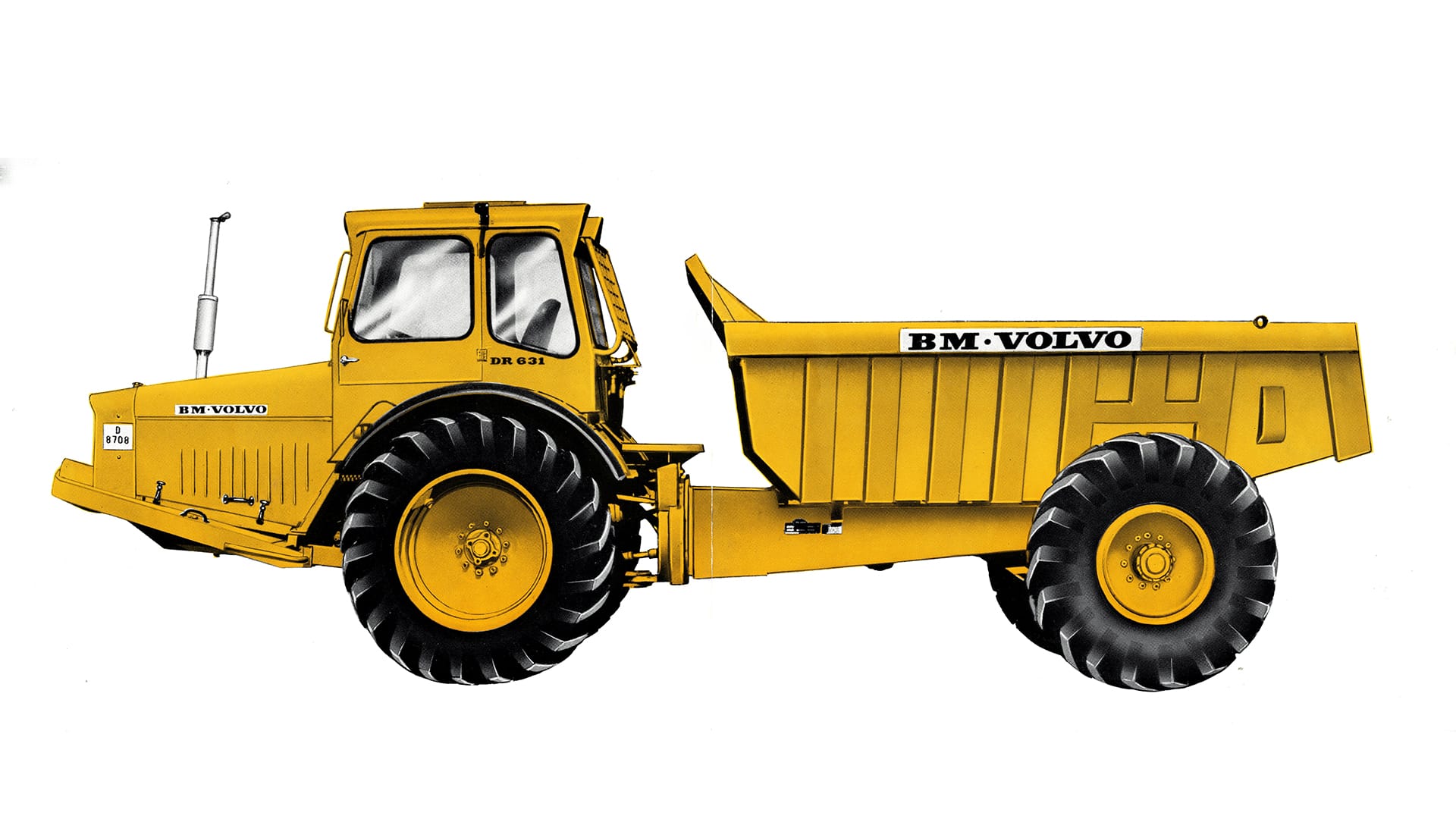

Gravel Charlie

The very first mass-produced and frame-steered dumper with four-wheel drive is launched in 1966 and bears the official model designation BM-Volvo DR631. It quickly earns the nickname "Gravel Charlie" after the man behind the unique construction: Carl Lihnell. The big advantage of a frame-steered dumper is that, unlike trailer dumpers, it constitutes a complete machine unit with frame steering, four-wheel drive, differential locks on both axles, and hub reduction on the rear axle.

Better mobility

With a frame-steered dumper, mobility increases dramatically, providing significant time savings as Sweden builds out the welfare state during the 1960s and 1970s with new roads and housing; the so-called Million Program alone would deliver 100,000 new homes each year. The idea for the frame-steered dumper is born shortly after World War II, in the small village of Braås north of Växjö, where the brothers Lennart and Carl Lihnell run Lihnell's Car & Engine Workshop. In a disused dairy, they construct an initial prototype, where the trailer behind the tractor is equipped with its own drive wheels. They apply for a patent on the solution, and in April 1947, the first cardan-driven cart is presented.

Timber-Kalle

Development continues with components from Volvo's trucks, including wheel axles and cardan axles. In 1950, AB Volvo acquires all shares in Bolinder-Munktell (BM) from Handelsbanken, making it a subsidiary. In the mid-1950s, a closer collaboration between BM and the Lihnell brothers' new company, Livab, begins. A few years later, a secret project is launched to develop a forestry machine with frame steering and all-wheel drive: "Timber-Kalle," launched in 1964. And now, the development gains momentum. The year after, in 1965, a cooperation agreement is signed between BM and Livab on manufacturing, sales, and marketing. As a consequence, the Livab brand disappears and is replaced by Volvo BM. Another year later, in 1966, "Gravel Charlie" is launched, which, just like "Timber-Kalle," handles tough conditions and can be driven in marshy ground - thanks to its large wheels, frame steering, four-wheel drive, and double differential locks.

The frame steering is achieved by the steering wheel affecting two hydraulic cylinders, controlled by a steering valve. This provides responsive steering with full traction in turns. The ring-laid frame link eliminates all risks of breakages between the engine and the load unit and allows for virtually unlimited skewing. "Gravel Charlie" can therefore be safely driven even in hilly terrain.

Mid-Steered dumpers

Already at this point, dumpers are sold as unified units, not as tractors with dumper trailers. Production takes place in the factory established by the Lihnell brothers in Braås as early as 1955. It remains a centre for the development and production of mid-steered dumpers. But despite "Gravel Charlie" being a historic milestone, it is not long-lived. The model is discontinued after just three years, in 1969, and only 400 units are manufactured. "Gravel Charlie" falls victim to internal competition. Already in 1967, DR860 is launched, a heavier, bogie-equipped dumper, which represents an improvement in virtually every area. A bogie is an undercarriage that is pivotable against a vehicle's body. The bogie usually has four wheels and spreads the load across more axles, thus reducing axle load, increasing load capacity, and improving cornering.

Increased capacity

The bogie solution stabilizes the material on the platform, the load capacity is 15 tons (compared to "Gravel Charlie's" 10 tons), and the basket holds eleven cubic meters (compared to six cubic meters). The driveline is sourced from the wheel loader LM840 but is reversed, and the steering wheel is removed. The engine is the powerful D50A with 112 hp. DR860 has a very special gearbox, developed by BM and British Rockford. It has two low-speed gears and two high-speed gears, both forward and reverse. Another feature is that four-wheel drive can be engaged on the two low-speed gears while driving. Theoretically, the skew between the front and rear body is infinite, and the front wheels always have contact with the ground. Together, all this means that the risk of getting stuck is minimal. Other novelties include disc brakes at the front and drum brakes at the rear.

Safe and comfortable

With DR860, passive safety takes a big step forward. For the first time, a dumper has a crash-tested safety cab. The rear window is reinforced and protected by a robust grid. The cab is completely isolated from the frame and engine compartment and rubber suspended. Inside the cab, ergonomics are well catered for, with all controls, levers, and instruments within reach and sight of the driver. The driver's seat can be individually adjusted, is parallel-sprung, and hydraulically dampened.

Displayed in Paris

DR860 attracts significant international attention at the Expomat 1968 trade fair in Paris, which is cut short due to the student riots that are the prelude to the late 1960s student revolts in many countries; in Sweden, the Student Union Building in Stockholm is occupied just a few weeks later. DR860 becomes a best-seller even outside Sweden. During 1970, 426 units are manufactured, and 58 percent are exported, a figure that increases to 85 percent over the years. A total of 11,292 DR860 and DR861 units are manufactured before the models are discontinued in 1979.