BM H10 Loader

Backward cab, forward-thinking design

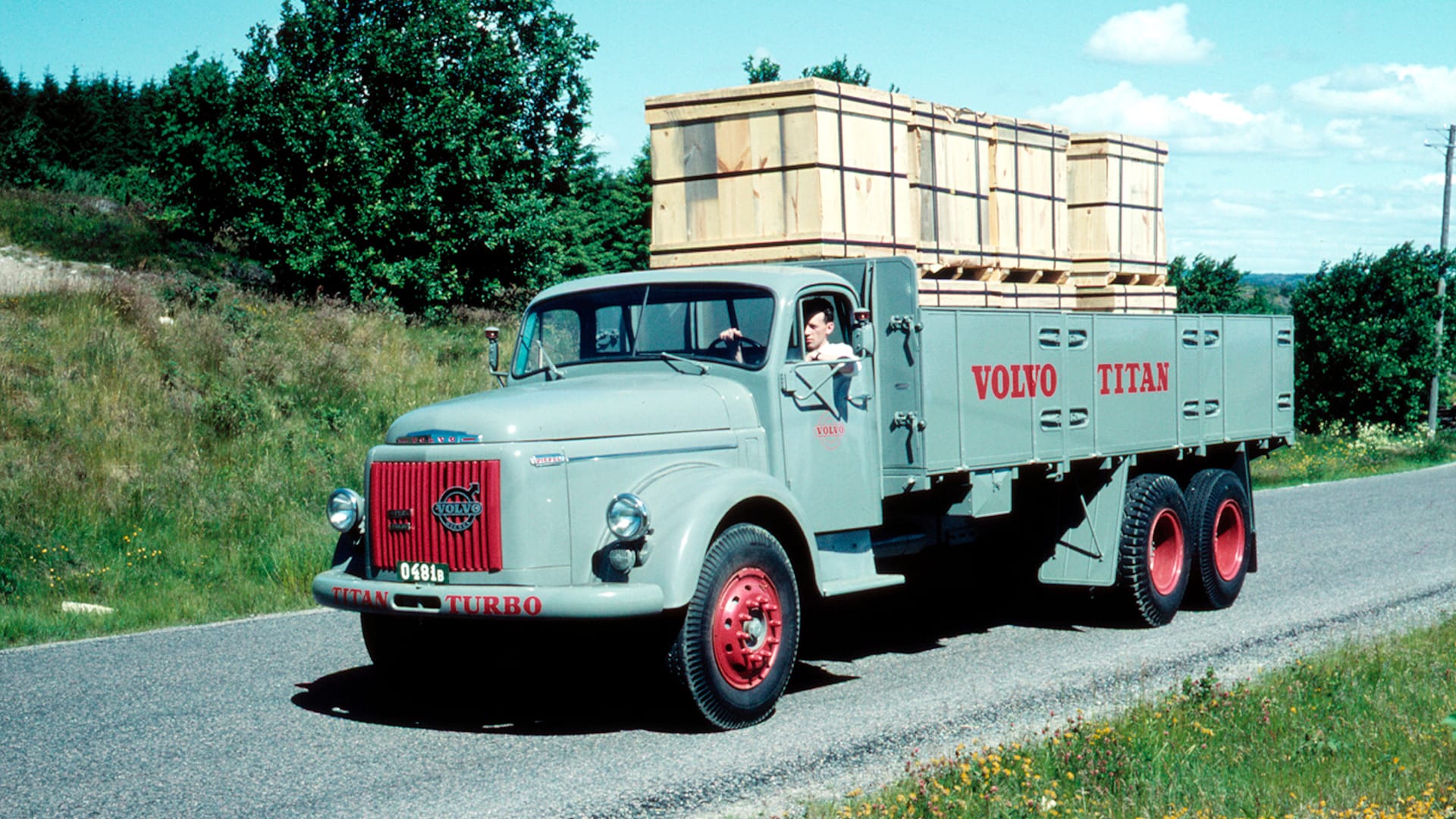

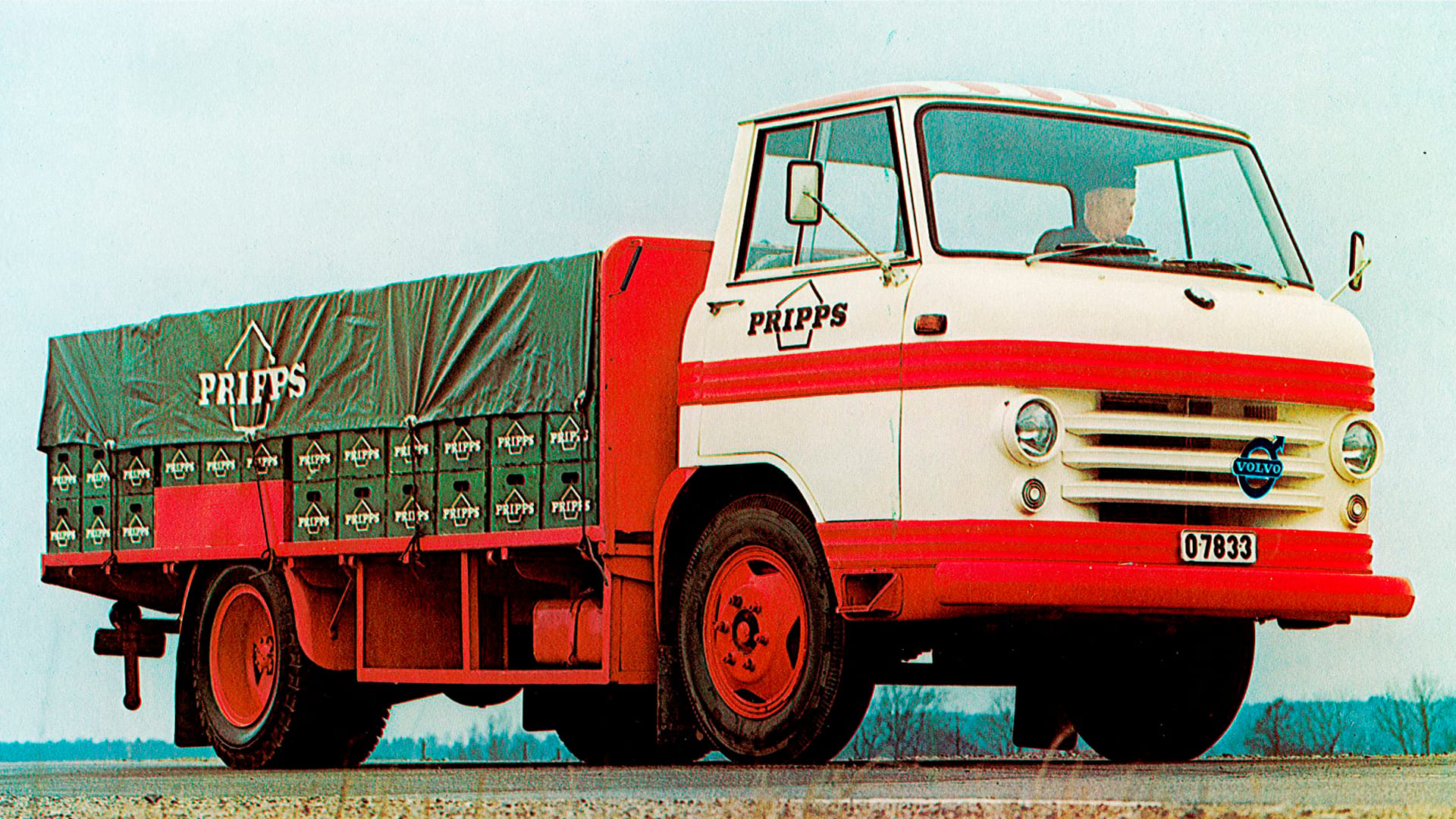

In 1954, the BM H10 is introduced, Volvo's first wheel loader that marks the beginning of the company's involvement in construction machinery. It is based on the conventional agricultural tractor BM35, but the driver's cab is backward-facing, allowing the large rear wheels to absorb the lifting forces.

The machine is equipped with the highly impressive parallel linkage, which means that the operator does not need to compensate to keep the implement parallel to the ground when lifting from the lowest to the highest position. A clever quick coupler allows the operator to switch between attachments such as a bucket, fork, and road scraper without even leaving the cab.

The BM H10 loads 1.7 tons in transport mode and is both robust and reliable. It quickly becomes popular. Behind this innovative design are Bröderna Lundbergs Mekaniska in Skellefteå and Bolinder-Munktell in Eskilstuna.

The versatility of the H10, allowing it to be used in various areas, makes it special. As stated in an early brochure: "The H-10 loader is versatile - it loads, unloads, transports, excavates, levels, tows, and can be used for snow removal and cleaning." The ability to equip the backhoe loader with different attachments is also crucial. The brochure continues the list: "For the H-10, there are suitable tools for loading and transporting soil, sand, gravel, gravel, lime, coal, coke, snow, sawdust, quarry stone, ore, concrete, palletized goods, boards, general cargo, timber, pulpwood, props, ribs, firewood, paper pulp bales, barrels, boxes, and barrels, etc."

The history of the backhoe loader begins as early as 1946, at the home of the Wigren brothers in Järbo, Gästrikland, who sell gravel from their own quarry. They have a Fordson front loader, which becomes terribly front-heavy and difficult to steer when loading heavily; the rear wheels mostly spin in the air. Eventually, it becomes faster to load by hand. But one day, the brothers realize that the loading equipment can be turned backward and forward to achieve better weight distribution on the tractor. The backhoe loader is invented.

The Lundberg brothers develop it

Several manufacturers are interested in the idea, including the brothers Göran and Birger Lundberg in Skellefteå. They grow up in the small village Norrböle in a family of ten siblings. Göran starts working in various mechanical workshops, and Birger becomes an apprentice welder. At home on their parents' farm, they start a forge and focus on developing their own backhoe loader.

The development is successful, and the BL (Bröderna Lundberg) loader sees the light of day - the world's first loader with three groundbreaking features: an attachment bracket, double-acting lift cylinders, and, most importantly, a parallel linkage. This means that the operator does not have to adjust the lift to keep the implement parallel to the ground. In pallet handling, the fork inclination is not affected when the pallet is lifted up and down, saving a lot of time.

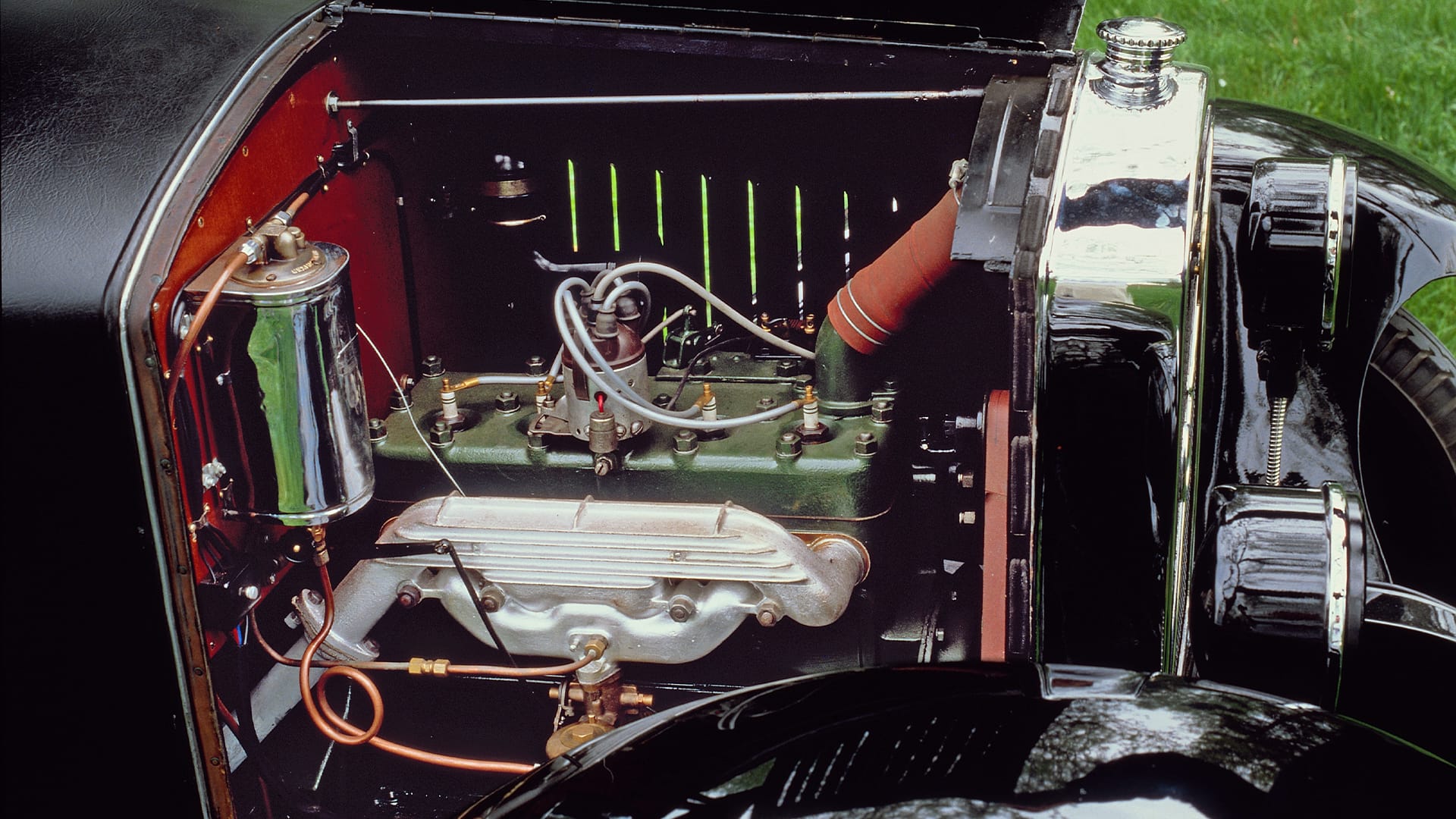

The first backjoe loader by the Lundberg brothers builds on tractors from Fordson, Nuffield, and Volvo T31. But it is when they start using the BM35, the conventional agricultural tractor that H10 is based upon, that the major successes come. The engine, drivetrain, and tires are taken from it, while the frame, loader, cab, electrical components, and hydraulics are manufactured by Bröderna Lundberg in Skellefteå, where the assembly of the H10 is also carried out. It weighs 5.1 tons, loads one ton, and has a bucket capacity of 400 litres. The diesel engine is three-cylinder, with a displacement of 3.4 litres and delivers 43 hp.

Durable construction

So, it is not the Lundberg brothers who invent the backhoe loader, but it is their development of the technology that leads to series production - and to collaboration with Bolinder-Munktell and Volvo. Up to 1962, a total of 2,700 H10 loaders are manufactured, used both in agriculture and forestry. The construction - with chassis, engine, and transmission from BM 35 - is durable, and many H10 loaders are still in operation.

Over the years, backhoe loaders will come to be considered risky to work with. The machine type is condemned in 1998 by the Labour Inspectorate as dangerous and unsafe. In a survey conducted by the authority, only 20 of the 207 inspected backhoe loaders have no remarks. But Volvo has long ceased production of backhoe loaders. The last one is of the LM/642 model and is manufactured in 1984. By then, almost 33,000 backhoe loaders have been produced, of which 26,000 are in Skellefteå.